Forlæng levetiden på dine CMM’er

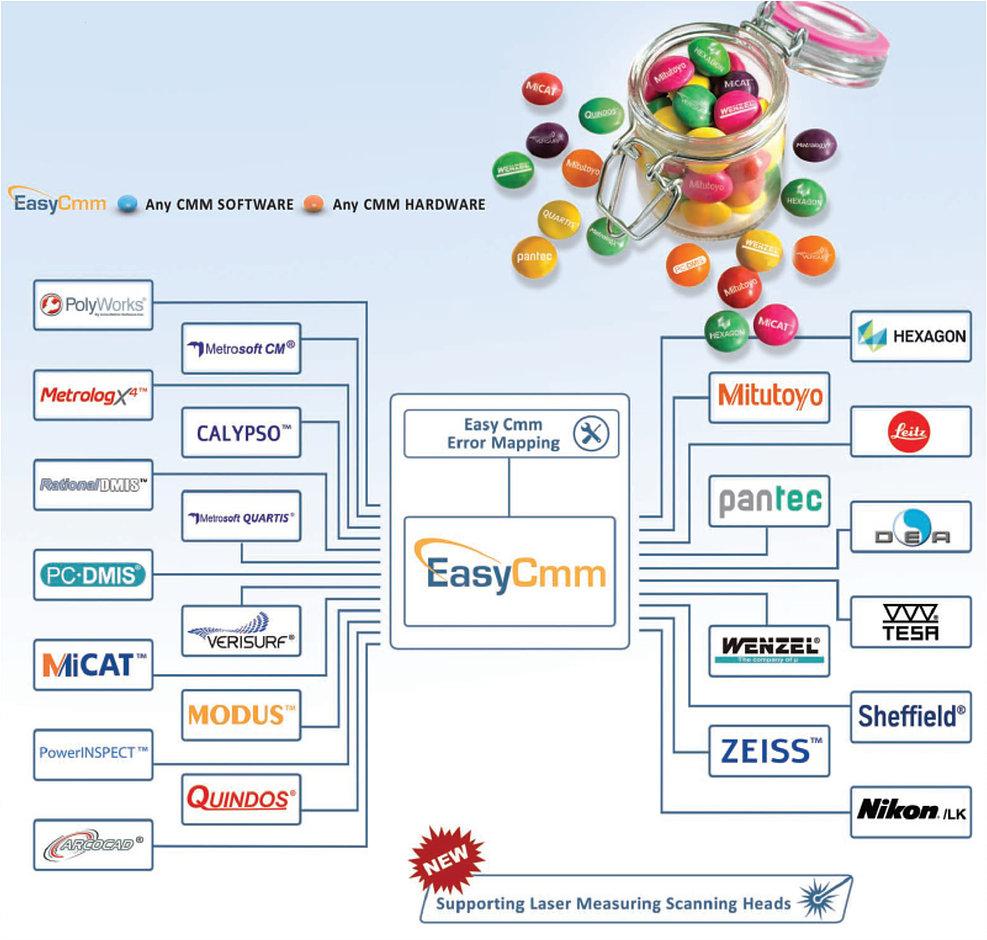

Why retrofit? De fleste CMM-strukturer er robuste og kan holde i mange år. Dog kan software, styresystemer og sensorer hurtigt blive forældede i takt med teknologiske fremskridt.

Renishaw Retrofit: En Game Changer

En Renishaw retrofit tilbyder en effektiv opgradering af eksisterende CMM’er.

Øget Præcision

Med den nyeste teknologi opnår du større nøjagtighed, hvilket er afgørende for kvalitetskontrol.

Hurtigere Målinger

Måleprocesserne bliver hurtigere, så du får resultater på kortere tid.

Mere Automatisering

Automatisering reducerer behovet for manuel indgriben, hvilket sparer tid og ressourcer.

Nyere Funktioner

Why retrofit? Retrofitting muliggør integration af avancerede funktioner og sensorer, som forbedrer produktiviteten.

CAD-Drevet Programmering

Med CAD-drevet programmering kan du let overføre designdata til målesystemet, hvilket mindsker fejl.

At opgradere med Renishaw retrofit sikrer, at dine CMM’er forbliver relevante og konkurrencedygtige, samtidig med at du forbedrer præcisionen og effektiviteten i din produktion.