Beskrivelse

Designed with usability in mind

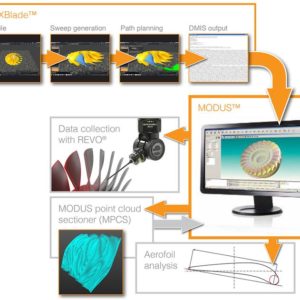

Based on the established and highly capable MODUS platform with support for Renishaw’s suite of 3- and 5-axis CMM sensor technologies, MODUS 2 has been designed with usability in mind. The innovative interface is simple for new users to learn and faster to program, resulting in unprecedented levels of productivity with or without a CAD model.

Usability by design

MODUS 2 has been designed with usability in mind. The innovative interface is simple for new users to learn and faster to program, resulting in unprecedented levels of productivity with or without a CAD model.

Based on the established and highly capable MODUS platform it offers optimal support for Renishaw’s suite of 3- and 5-axis CMM sensor technologies.

User experience

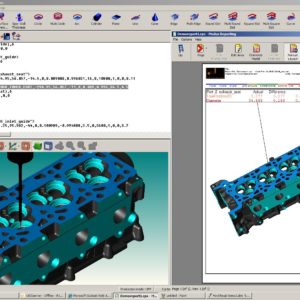

From simple manual CMM operation through to complex part measurement on multi-axis systems, MODUS 2 adapts automatically and only offers functionality relevant to the current task.

The user experience is designed to be identical whether the software is connected to a ‘live’ CMM or working in an offline environment where full simulation with speed control allows measurement sequence development and visualisation.

Future-proofed

The MODUS 2 metrology software suite is a future-proofed investment, guaranteeing availability of the latest sensor and controller technology advancements from Renishaw. This will include future sensors for the 5-axis measurement product range, which delivers unprecedented speed and measurement flexibility, whilst avoiding the speed versus accuracy compromises inherent in conventional techniques.

MODUS 2 highlights

- Use of the I++ DME communications protocol provides support for third-party CMM controllers, in addition to Renishaw’s UCC range of universal CMM controllers.

- Support for 5-axis measurement systems.

- OSM technology enables the automatic creation of efficient, collision free, motion paths around the part.

- Bespoke measurement strategies can be created and shared with other users to ensure consistent measurement of all parts, regardless of the programmer.

- CAD-driven offline programming, with support for neutral formats of IGES, STEP, Parasolid® and VDA-FS.

- High quality integration with the CATIA® (v5 and v4), Siemens® NX™ (previously Unigraphics®), Pro/E® and SolidWorks® CAD/CAM solutions.

- Full motion simulation and collision detection, including 5-axis moves.

- Native DMIS support.

- Certified mathematical algorithms.

- Powerful text and graphical reporting.

- Flexible output of results data including certified Q-DAS®.